Description

A pull lift is a type of vertical transportation equipment designed to lift people or materials to elevated locations. It typically consists of a platform or cage that is pulled upwards by a cable or chain system. Pull lifts are commonly used in industrial settings, construction sites, and maintenance applications.

Types of Pull Lifts

-

- Construction pull lifts: Designed for use on construction sites, often with a larger platform capacity and the ability to be moved around the site.

- Maintenance pull lifts: Used for maintenance and inspection tasks, often with a smaller platform and a focus on maneuverability.

- Personnel pull lifts: Used to transport personnel to elevated work areas, such as overhead cranes or storage racks.

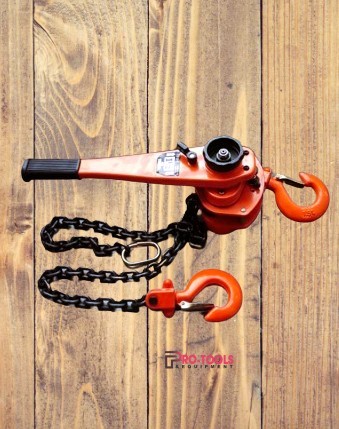

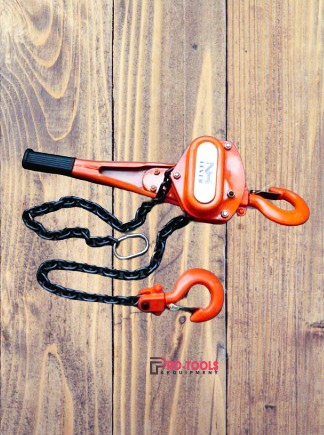

Components of a Pull Lift

- Platform or cage: The area where people or materials are transported.

- Hoist mechanism: The system that raises and lowers the platform.

- Control panel: Used to operate the lift.

- Safety features: Includes emergency stop buttons, overload protection, and safety harnesses.

Benefits of Using Pull Lifts

- Improved efficiency: Reduces the time and effort required for manual lifting.

- Increased safety: Minimizes the risk of falls and injuries.

- Versatility: Can be used for a variety of tasks and applications.

- Cost-effective: Can be a more economical solution compared to other lifting equipment.

Safety Considerations

- Load capacity: Ensure the pull lift is rated for the weight of the load.

- Proper installation: Install the pull lift according to manufacturer’s guidelines.

- Operator training: Provide comprehensive training to operators.

- Regular inspection: Conduct routine inspections to identify potential issues.

- Safety devices: Utilize safety features such as emergency stop buttons and overload protection.

Reviews

There are no reviews yet.